3

UA-24279210-1---

產品中心

Transmission Diffraction Gratings, near IR

發布時間: 2020-04-16 17:04

LightSmyth

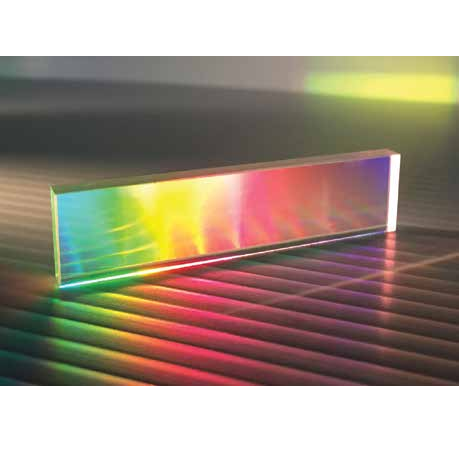

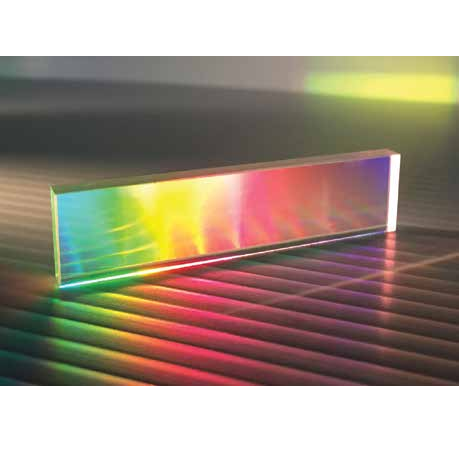

LightSmyth utilizes a unique patterning method, DUV projection photolithography and reactive ion etch, that offers a number of important advantages for transmission diffraction gratings. The same diffraction grating type may be used in a variety of applications.

Low wavefront deformation, even with thinner substrates, are of special value to pulse compression diffraction gratings. High diffraction efficiency (95% typical) allows our customers to minimize optical losses in multi-pass configurations. High energy pulsed and CW laser systems will benefit from high optical damage threshold of our diffraction gratings. They contain no organic materials and can withstand up to 500° C temperature with no performance degradation.

Unlike reflection diffraction gratings, transmission diffraction gratings may be polarization independent and operate at the optimal Littrow angle with conveniently large angular separation between the input and diffracted beam.

Robust and easily scalable fabrication offers economical, cost-effective diffraction gratings with rock-stable batch-to-batch performance.

Transmission Diffraction Gratings, near IR特點:

Transmission Diffraction Gratings, near IR

Transmission Diffraction Gratings, near IR

Low wavefront deformation, even with thinner substrates, are of special value to pulse compression diffraction gratings. High diffraction efficiency (95% typical) allows our customers to minimize optical losses in multi-pass configurations. High energy pulsed and CW laser systems will benefit from high optical damage threshold of our diffraction gratings. They contain no organic materials and can withstand up to 500° C temperature with no performance degradation.

Unlike reflection diffraction gratings, transmission diffraction gratings may be polarization independent and operate at the optimal Littrow angle with conveniently large angular separation between the input and diffracted beam.

Robust and easily scalable fabrication offers economical, cost-effective diffraction gratings with rock-stable batch-to-batch performance.

Transmission Diffraction Gratings, near IR特點:

- Exceptional diffraction efficiency for selected polarization

- Special design for broad passband and low angular sensitivity

- Ultra-polished quartz substrate minimizes wave front deformation in transmission

- Uses only fused silica and highly robust dielectric materials

- No polymers or organics are used

- Each diffraction grating is a master; ultra-low scatter

- Extremely precise line density (line density uniformity <0.001 lines/mm)

服務熱線:886-2-2655-2200 業務咨詢:151 / 維修校正:185

產品

文章

搜索

名稱描述內容

【關鍵字搜索】:

請於欄位下方先點選"內容"

當前位置: